I had been tasked with the job of building a replacement kitchen unit to replace an old one that had been ripped out during refurbishment works at Sheffield Hackspace The space needed somewhere that people could make food and drinks but also served as an area for PCB etching and other activities using hazardous chemicals without the risk of cross contamination.

I was given a specification of what the ‘Wet Bench’ must have to make it practically useful and safe in the environment it would be set in, the list follows:

- The height of the worksurface must be at the same level as the window ledge

- Span the width from the door to the start of the 3rd window inwards

- House two sinks, one at either end

- Utilise storage space below with at least one shelf

- Provide a space under each of the sinks to accommodate a water heater at one end and a space for a bucket under the other.

The bench will span 2600mm wide and stand off the wall 600mm. There will be a sink situated at either end, the one of the right will be for food and drinks it will have a water heater sat below, the sink on the left will be for handling hazardous substances when doing activeness such as PCB etching, when these types of activities do occur the trap of the sink can be removed and a bucket can be placed below. There will be a shelf in the middle of the frame that will be used as storage.

With all of this in mind I needed to choose some material to use. I decided to go with some PSE (Plain Square Edge) timber. I used 69×69 for the posts and 20×69 for the through tenons.

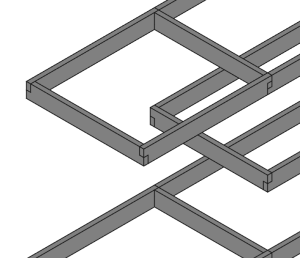

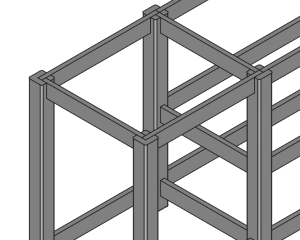

The frame will be constructed using a series of mortis and through tenon joints. The reason I have opted for this method is because they are a strong and reliable joint because it gives you a large surface area to apply glue to.

Now that I had all of these details I could begin to make a model to work to, I used FreeCAD to design the frame. You can see that the two rectangular areas that are directly below the sink openings leave space for a water heater on the right and a bucket or tank on the left. The OSB shelf on very bottom is split in four sections, this is so that the boards under neigh the sink can be replaced in the case of any water damage. The central shelf allows for additional storage, all of the posts have had there edges rounded over to give them a more aesthetic look and smoother to touch.

To begin work I started by cutting all of the material down to the required length using a mitre saw. For cutting a series of components witch were all the same I stacked the material on top of each other and ensured that the end was square, this way I could get up to 4 of the same lengths at once saving time in the build.

After this process had been completed I moved on to marking out for the mortises on the posts. Whilst doing this I realise that it would be much easier to use some form of a jig to do the marking, so I decided to make one. As shown in the image below there is a base set at 90 and four supports on either side to keep the post square and the mortises marked out at the corresponding heights. All I had to do now was to place the posts in the jig and draw the top and bottom line then join them together using a mortis marking gauge.

With all of the mortises marked out I used a plunge router with an 18mm 2-flut cutting bit. I set up the fense on the router so that the cutter was positioned in the centre of the post, the depth stop was then set to 45mm (2/3 the way in). I clamped two pices of scrap timber on either side of the post to prevent me from inadvertently overshooting the mortise. When routing the mortise I went down in 3 passes when removing material.

Now this task had been completed I rounded over the edges of the posts using a 1/4″ round over bit. I ran the cutter over a scrap piece of timber first to ensure that the router was set correctly and make any adjustments if needed. With all of the mortises routed they where squared off using a chisel.

For cutting the through tenons I marked them up using a combination square. Each tenon has either 1/2 or 1/3 x 20mm removed from the edge, the 1/3 tenons are for the central sections where ‘T”s are formed. These joints where machined using a band saw, I set up the fens and an end stop so that I could run through all of the necessary parts before resetting the machine to of the other 1/3 through tenors.

I now begin to assemble the frame, I started by assembling the two rectangular shaped units that would sit on either end, these two individual units would be joined together by the cross shelf supports making it one unit. The joints where fixed together using an expanding glue which fills gaps. Once glue had been applied to the joint and the through tenon had been inserted it was secured in place using a few wood screws, this pulls the joint tight and prevents it from setting uneven or out of square.

Once the two end sections had been created I set out to join them both together. I laid one of the side units on its side and glued in all of the 6 through tenons and secured them in place.

I then proceeded to measure and cut out some shelfs for the frame, I used 18mm OSB. The bottom section of the frames shelfs where cut individual in four sections, this was the same for the central shelf but this time it was split in to two parts, A number of screws where then added to keep the shelfs held down and secure.

The worktop was then cut size and mounted on top of the frame and secured in place. The two holes for the sinks where then cut out using a router and the taps where installed. All that was left now was to plumb in the sink and connect the taps up to the water main.

Overall this has been a great build and I have gained more skills from doing so. If I was to do this job again I’d improve the frame design and make it and construct it as a cabinet using sheet materials. This in turn would then allow me to hang doors on the exterior, witch would make the presentation of the work surface much more neater.